Peek Seat Material Temperature Range

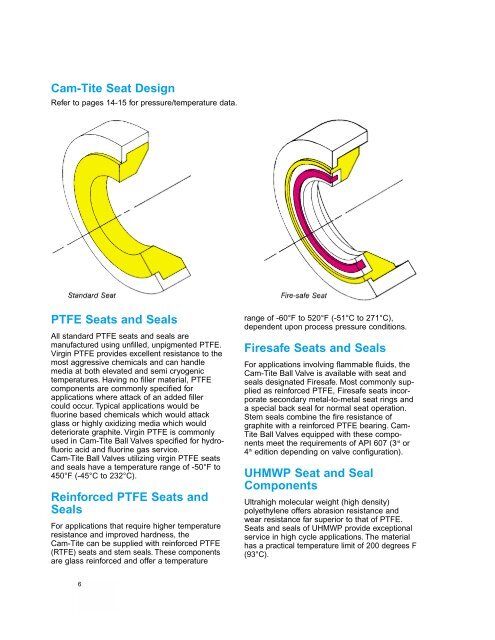

Displays good resistance to wear and deformation under load.

Peek seat material temperature range. Research peek properties bearing and glass filled materials at curbell plastics supplier. Peek k best suited for high temperature and pressure service suitable for tobacco and nuclear service. Peek plastic is a stiff high temperature material with outstanding chemical resistance. The material is non porous thus is good for monomer services that can polymerize and destroy ptfe based seats peek offers excellent corrosion resistance peek has fda approval in the unfilled grade.

Maximum service temperature. This material is very rigid suitable for high pressure up to 5000psi dependant on valve size and temperature range of 50 f to 180 f. Ball valve seat guide for steam use material technical description typical colour approx. Torque adders to the standard seats indi cated in catalog page d delrin this seat is very rigid and does not undergo cold fl ow.

Standard seat selections seat code material technical description color approx. Unfilled is tan and the filled is black. Can be supplied in both virgin unfilled or as filled compounded material. The seat has excellent heat and chemical resistance conforming with the requirements of ul94 vo for its flame retardancy.

It can withstand pressures of up to 6000 psi dependent on valve size and a temperature range of 70 f to 180 f. The crystalline nature of peek contributes to its. Than peek extensive testing carried out at the university of leeds in the uk and by leading global valve oems compared the performance of devlon v api against a range of the most common thermoplastic materials used in valve seat applications. Delrin also withstands nuclear radiation at does of up to.

Delrin can withstand pressures of up to 6000 psi dependent on valve size and a temperature range of 57ºc to 82ºc. Retains all key features and benefits of peek 450g but retains physical properties to a higher temperature. Swelless seat peek seats have high mechanical strength at a wide range of temperatures. It is technically feasible to process granular peek into filament form and 3d printing parts from the filament material using fused deposition modeling fdm or fused filament fabrication fff technology.

Temperature 70 f to 550 f. In the range of its melting temperature it can be processed using injection moulding or extrusion methods. The benefits of devlon v api superior pressure temperature operating range in comparison.