Phenolic Plastic Temperature Range

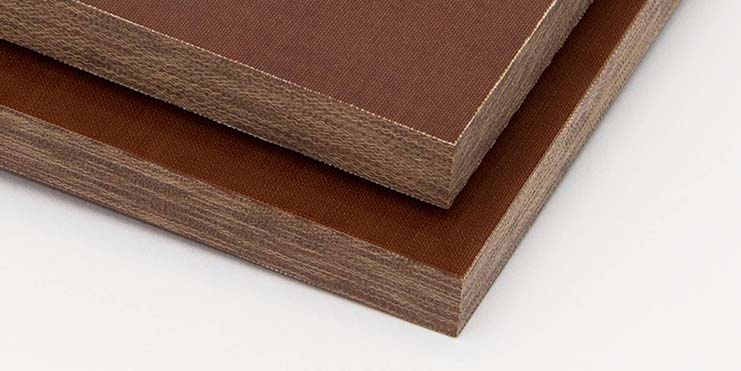

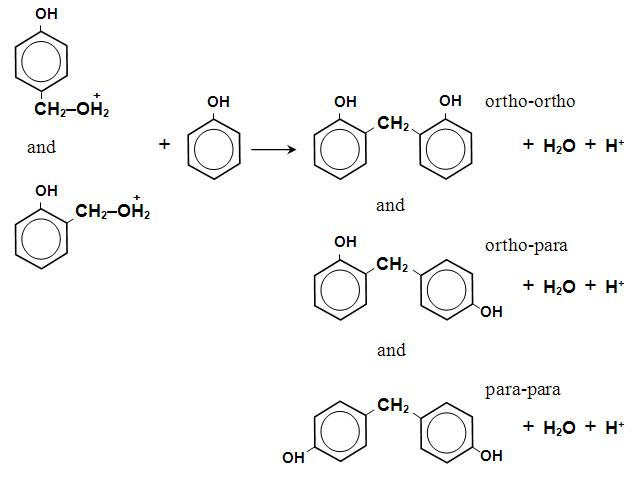

Phenol formaldehyde resins pf or phenolic resins are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde used as the basis for bakelite pfs were the first commercial synthetic resins plastics they have been widely used for the production of molded products including billiard balls laboratory countertops and as coatings and adhesives.

Phenolic plastic temperature range. Plenco thermoset compounds are suitable for evaluation in industrial and consumer applications which require molded properties to be maximized but unit cost to be minimized. Linen reinforced phenolic nema l per mil i 24768 15. Normal electrical applications moderate mechanical strength continuous operating temperature of 250 f. Phenolic washers have low moisture absorption so they won t expand or become brittle over time.

For technical drawings and 3 d models click on a part number. Epoxy resins are among the most versatile and widely used plastics in the electronics field. The first issue of plastics magazine october 1925 featured bakelite on its cover and included the article bakelite what it is by allan brown. Phenolic nema and mil specifications table chart.

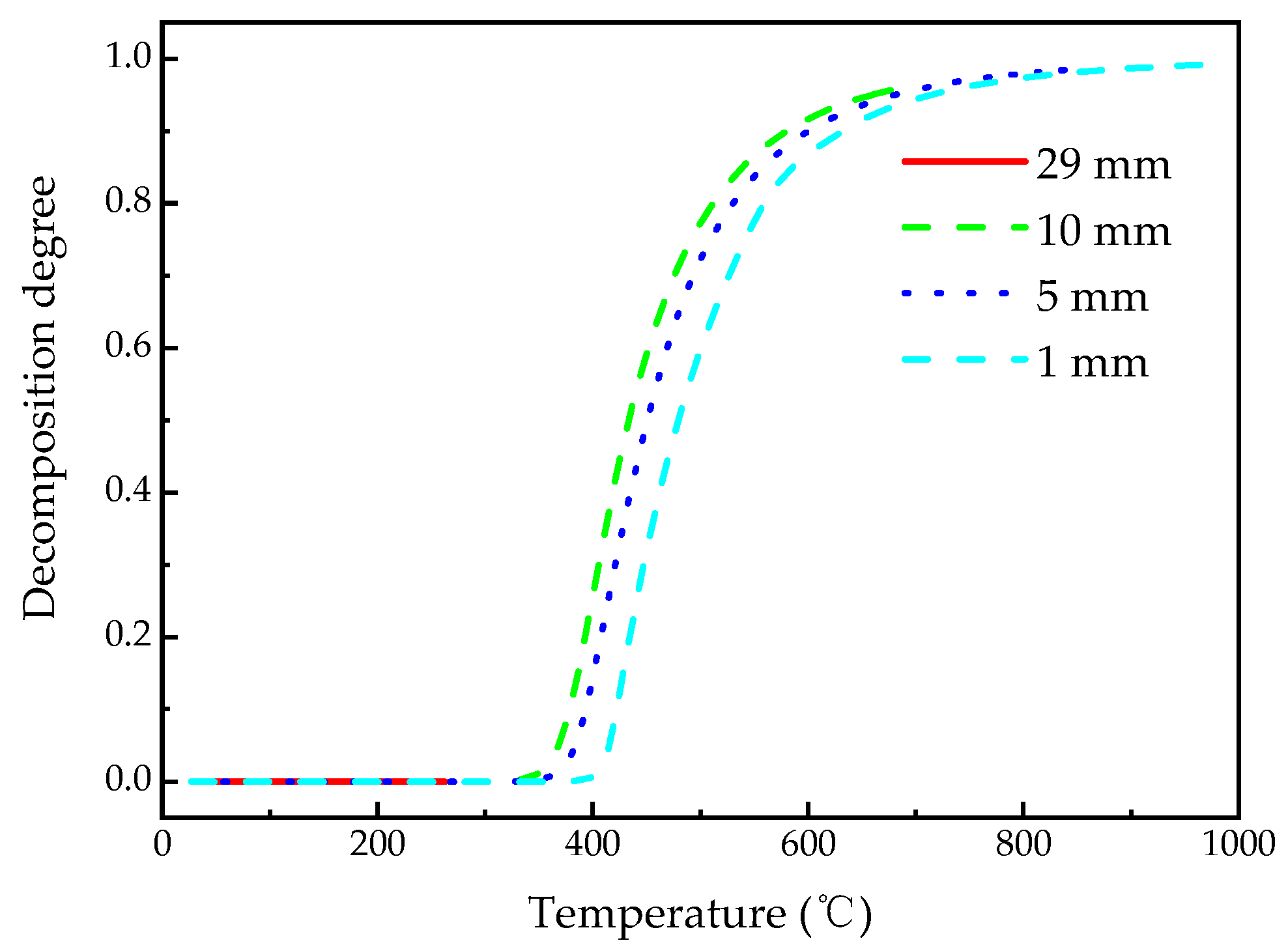

The self ignition temperature of the phenolic resin is approximately 600 c and the limiting oxygen index loi is in the range of 40 49. The article emphasized that bakelite came in various forms. Good mechanical and impact strength with contiunuous operating temperature of 250 f. Color ranges from red brown to yellow brown.

Phenolic composites are largely used in the aircraft interior and mass transit industries buses railways with interest increasing in marine applications. The range of colors available included black brown red yellow green gray blue and blends of two or more of these. Plastics engineering company manufactures a full range of phenolic molding materials. Canvas reinforced phenolic nema c per mil i 24768 16 type fbm nema ce per mil i 24768 14 type fbg.

Phenolic materials are available in sheets tubes rods blocks as well as specified shapes. G 10 has extremely high mechanical strength good dielectric loss properties and electrical strength both wet and dry. Glass based phenolic material specifications g 10 s natural color is typically a yellowish to light green. Insulation material temperature range.