Pre Vacuum Autoclave Definition

Pre and post vacuum class b autoclave reliable and robust class b autoclaves intended to deliver highest quality of sterilization.

Pre vacuum autoclave definition. An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure temperature autoclaves are used in medical applications to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. With their large capacity from 75 up to 200 liters they cover a large field of applications for hospitals medical centers and operating theaters. This b stage material requires cold storage to. Though both types of autoclaves sterilize through high temperature steam and use pressure as a means to allow steam to displace ambient air in the chamber to penetrate sterilization media.

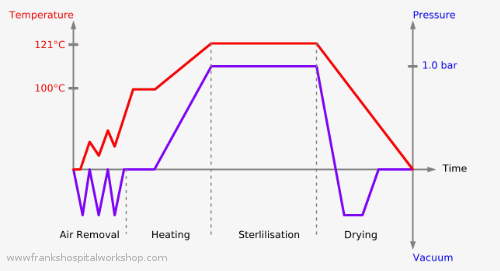

Autoclaves function primarily through either gravity or vacuum induced or pre vacuum pre vac sterilization methods though some types of autoclaves combine both methods to sterilize. The pre vacuum uses a powerful vacuum pump to ensure the removal of all the air from within the chamber prior to sterilization. Syringes contact lenses certain types of media etc require special cycle configurations that employ pressure or temperature ramping for instance. In addition it is built to run continuously.

The powerful water ring vacuum pump provides for fast pre and post vacuum air removal. Medium autoclave for dental and clinical waste disposal the azteca ac medium sterilizer family consists of pre and post vacuum sterilizers autoclaves. The ehs is our fastest tabletop autoclave. Pre preg is pre impregnated composite fibers where a thermoset polymer matrix material such as epoxy or a thermoplastic resin is already present the fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture.

Steam pressure temperature and time. Gravity and vacuum cycles are the most commonly utilized steam sterilization cycles as they can accommodate a wide variety of autoclave load types. The basic principle of steam sterilization as accomplished in an autoclave is to expose each item to direct steam contact at the required temperature and pressure for the specified time. In the absence of air steam is able to penetrate to all instrument surface including inside the narrow lumens of hollow instruments such as complete dental handpieces and scopes.

Thus there are four parameters of steam sterilization. This is achieved with a jacketed double walled chamber which acts as an instant supply of steam and keeps the autoclave warm and ready for use. Industrial autoclaves are used in industrial applications.